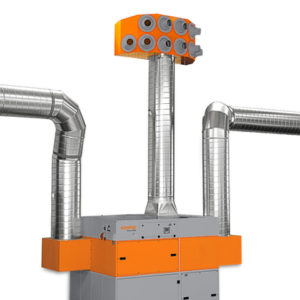

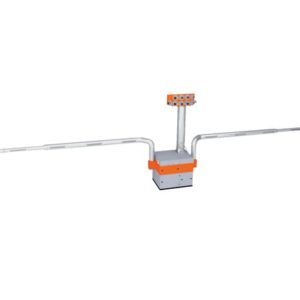

WeldFil Compact Welding Smoke Extraction Unit

WeldFil Compact units offer a plug-and-play welding smoke extraction system that is ready to use.

The solid yet compact welding smoke extraction system is ideally suited for factory buildings and welding shops with high levels of smoke and dust. Supplied ready to plug in, the WeldFil Compact is equipped with forklift pockets and lifting eyes. Installation as a central extraction and filter system for multiple welding workstations, cutting machines, and welding robots is remarkably quick. It utilizes KemTex® ePTFE membrane filter cartridges for ultra-fine dust particles and will separate minute matter below 0.1 µm. The Weldfil Compact extraction filter unit has W3/IFA Certification and is also suitable for use when machining chromium-nickel steel.

There are seven WeldFil Compact models that offer an extraction capacity that ranges from 1,250 m3 or 1,635 cubic yards to 8,640 m3 or 11,300 cubic yards per hour.

Get A Quote

technical specs

| Filters | |

|---|---|

Filter stages | 1 |

Filter method | Cleanable filter |

Filter cleaning method | Rotating nozzle |

Filter surface | 10 m² |

Number filter elements | 3 – 12 |

Filter surface total | 30 – 120 m² |

Type of filter | Filter cartridge |

Filter material | ePTFE membrane |

Filter efficiency | > 99.99 % |

Dust classification | M |

| Basic Data | |

|---|---|

Extraction capacity min. | 725 cfm |

Extraction capacity (max.) | 5000 cfm |

Air flow rate (max.) | 1500 cfm |

Vacuum min. | 2600 Pa |

Vacuum | 2600-2280 Pa |

Working pressure in PA | 2280 Pa |

Dimensions (w x t x h) | 38 x 38 x 83 in |

Weight | 903 lbs |

Motor power | 5 hp |

Power supply | 3 x 460 V / 60 Hz |

Rated current | 8.5 A |

Noise level | 65 dB(A) |

- High levels of smoke and dust

- Welding and grinding shops

- Training centres and robotic welding lines

- Laser, plasma and flame cutting systems

- Can be installed outdoors

- Contamination-free dust collection due to compressed air fixation of dust collection containers

- Uninterrupted continuous operation due to automatic differential pressure-controlled filter cleaning

- Little noise emission due to a low noise level

- Considerable energy cost savings by using the automatic extraction volume control

- Convenient operation due to intelligent control via touch screen with diagnostic system

- Flexible integration of the control system into third-party systems such as cutting equipment due to potential-free contacts

- Best health protection for employees by use of KemTex® ePTFE cartridges with surface filtration

- Automatic filter cleaning, pressure-controlled

- Control via touch screen

- W3/IFA certified

- KemTex® ePTFE filter cartridges

- Dust collection container with pneumatic lifting device

- Automatic extraction volume control (optional)