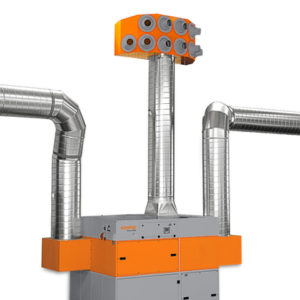

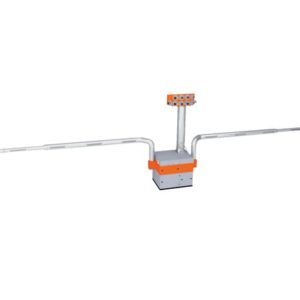

WeldFil Welding Smoke Extraction Unit

WeldFil is a welding smoke extraction unit that is available in a variety of maximum capacities for a range of workstations and different applications.

The Weldfil central fume extraction unit is robust, reliable, and solid. It handles high levels of smoke and dust and is ideally suited to large welding shops and training centers. It can be used for the full range of welding equipment from connecting to cutting machines.

The KemTex® ePTFE membrane filter cartridges used with the WeldFil remove ultra-fine dust particles and can separate minute matter, even below 0.1 µm. You can grow the modular system with flexible extensions if your requirements change. Eight product variants offer extraction capacities from 7,500 m3 or 9,810 cubic yards to 26.640 m3 or 34,844 cubic yards per hour.

Get A Quote

technical specs

| Filter | |

|---|---|

Filter stages | 1 |

Filter method | Cleanable filter |

Filter cleaning method | Rotating nozzle |

Filter surface | 20 m² |

Filter Elements | 7 – 37 |

Filter surface total | 140 – 720 m² |

Type of filter | Filter cartridge |

Filter material | ePTFE membrane |

Filter efficiency | > 99.99 % |

Dust classification | M |

| Basic Data | |

|---|---|

Extraction capacity | 4450 – 15500 cfm |

Air flow rate (max.) | 15000 m³/h |

Vacuum | 2600 – 2000 Pa |

Dimensions (w x t x h) | 112 x 74 x 105 in |

Weight | 3450 lbs |

Motor power | 15 hp |

Power supply | 3 x 460 V / 60 Hz |

Rated current | 18 A |

Noise level | 65 dB(A) |

- High levels of smoke and dust

- Training centres and robotic welding lines

- Laser, plasma and flame cutting systems

- Can be installed outdoors

- Welding and grinding shops

- Contamination-free dust collection due to compressed air fixation of dust collection containers

- Uninterrupted continuous operation due to automatic differential pressure-controlled filter cleaning

- Little noise emission due to a low noise level

- Expandable due to simple modular construction

- Considerable energy cost savings by using the automatic extraction volume control

- Convenient operation due to intelligent control via touch screen with diagnostic system

- Flexible integration of the control system into third-party systems such as cutting equipment due to potential-free contacts

- Best health protection for employees by use of KemTex® ePTFE cartridges with surface filtration

- Automatic filter cleaning, pressure-controlled

- Control via touch screen

- KemTex® ePTFE filter cartridges

- Dust collection container with pneumatic lifting device

- Modular design

- Automatic extraction volume control (optional)