Welding can be a hot and dangerous job because of a welder’s constant proximity to flame and molten metal. But oddly enough, the biggest danger to welders doesn’t come from burns. That is not to say that there won’t be the occasional burn, as any welder can attest, but the bigger danger is the fumes that welding generates. If you breathe welding fumes, it will damage your lungs and cause many different health problems over time so proper ventilation is crucial to a welder’s health.

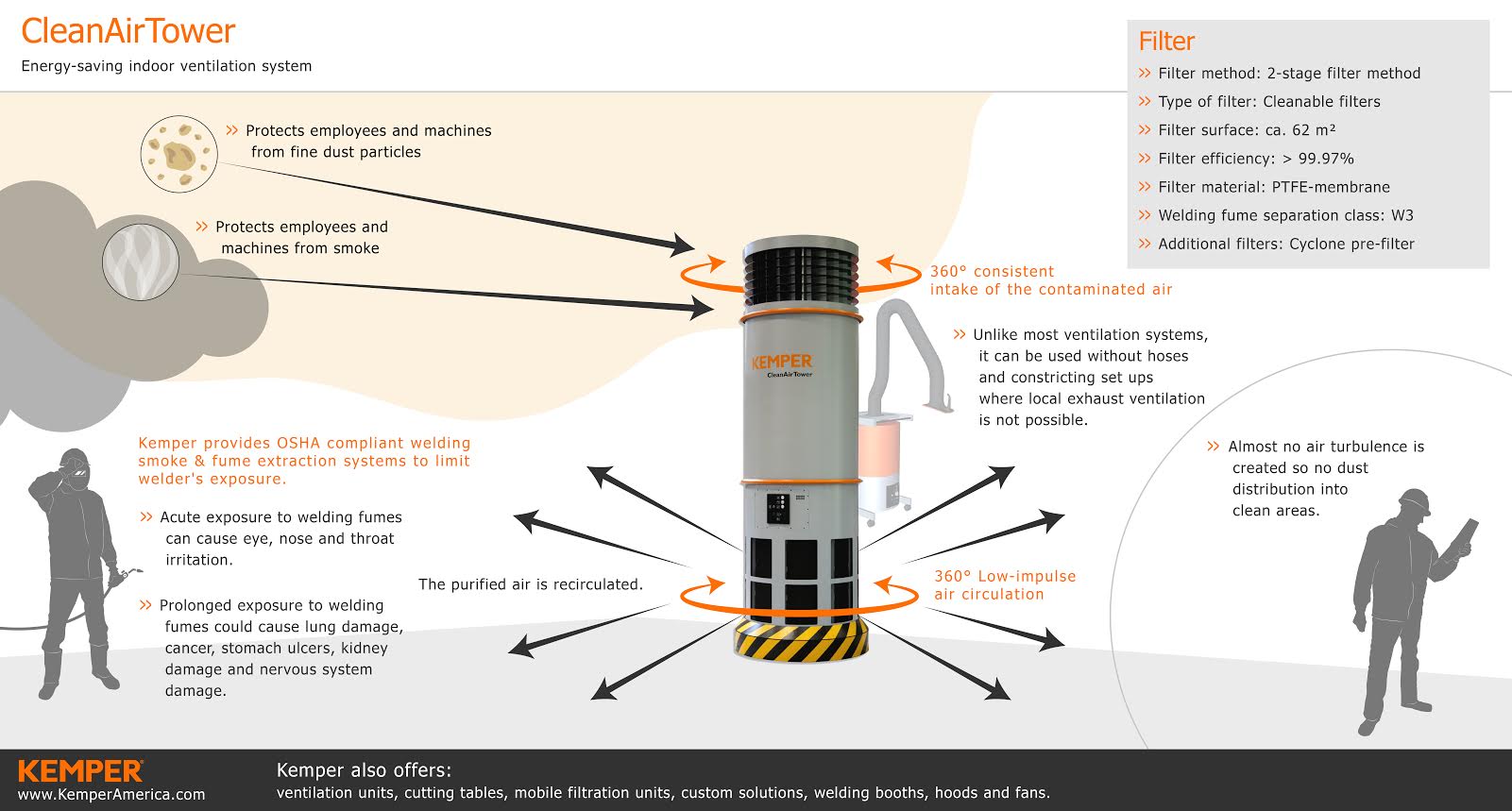

Kemper created the Clean Air Tower to be used for local extraction of fumes where there is insufficient ventilation. The Clean Air Tower provides clean, recirculated air free from any fine dust that may become airborne during welding, while causing barely any air turbulence of its own. This is very important because it not only protects your workers, but also helps minimize maintenance of welding machinery, preventing potentially harmful fine dust from getting into tools and equipment.The tower functions according to the displacement ventilation principle recommended by most health and safety standards.

The Clean Air Tower is perfect for:

- Production and logistic areas

- Environments where the smoke and dust sources constantly change

- Supplementing other local exhaust ventilation

- Workshops that don’t have adequate local exhaust ventilation or where it is otherwise not possible

The Clean Air Tower’s ability to produce safe, recirculated air in areas where there is no ventilation available can be a life saver for many workshops. The Clean Air Tower features:

- A Cyclone Pre Filter

- A W3 welding fume separation class

- Greater than 99.97% filter efficiency

- A ca. 32 m filter surface

- A 2 stage PTFE membrane cleanable filter

There is no longer any excuse for welders to work with inadequate ventilation. Protect your company and your workers with a Clean Air Tower today and avoid health problems in the future.