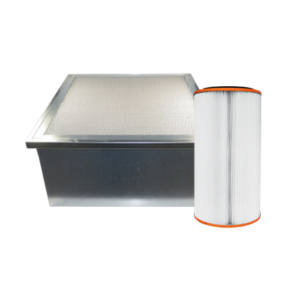

FilterMaster XL Mobile Welding Fume Extractor

$8,221.14 – $8,421.14

Our FilterMaster XL is the base model of all our cartridge-style filter units. Equipped with an ultra-modern and highly efficient KemTex ePTFE membrane filter cartridge, this mobile welding fume extractor provides the best protection against harmful high-alloyed metals. It’s especially suited for the extraction of welding smoke where Hexavalent Chromium (CrVI) is a concern.

With a separation rate of > 99.9%, this unit is suitable for the removal of alveolar-damaging dust (dust particles < 0.4 µm that can enter your bloodstream and cause serious diseases).

Advantages of the FilterMaster XL’s KemTex ePTFE membrane filter cartridge include:

- High Collection Efficiency

- Re-usable Self-Cleaning Filter

- Automatic Cleaning Cycle

- Integrated Monitor for the Filter Surface that Indicates When a Cleaning Cycle is Needed

technical specs

| Basic Information | Unit |

|---|---|

Fan Performance | 1700 cfm |

Suction Performance | 720 cfm (at hood) |

Power | 2 hp |

Voltage | 115 V |

Compressed Air Supply | 5 – 6 bar (90 psi) |

Noise Level | 69 dB (A) |

Separation Rate | >99.9% |

Weight (without arm) | 298 lbs |

Dimensions (W x D x H) | 34″ x 26″ x 58″ |

| Part # | Description |

|---|---|

62100100x | 7 ft |

62100101x | 10 ft |

62100102x | 14 ft |

- Changing workstations

- Welding/maintenance shops

- School shop environments